Comparing the Different Types of Fire Sprinkler Systems

The first step to learning about fire sprinkler systems is understanding the different types of sprinkler systems, and what type of facilities each is most efficient for. The type of sprinkler system needed for a facility changes based on several factors:

- What type of equipment/inventory is stored in the facility?

- How is the equipment/inventory being stored?

- Would a sprinkler discharge cause expensive damage to any inventory or equipment?

- How fast does the sprinkler system need to be activated?

Depending on the answers to the questions above, certain sprinkler system types may be rendered ineffective and unusable. Let’s take a look at the different sprinkler system types and what type of facility for which they are best:

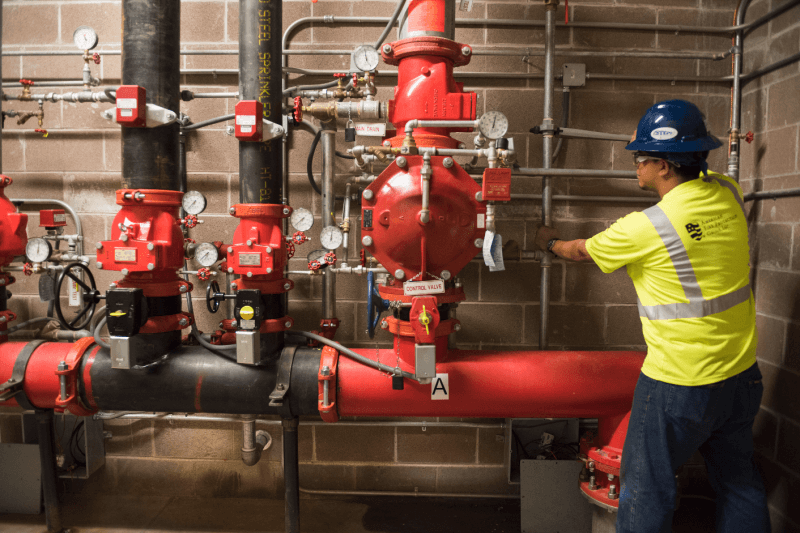

Wet Pipe Sprinkler System

This is the most common type of fire sprinkler system. The pipes in the facility constantly have pressurized water stored, ready to discharge upon activation. The sprinkler heads are activated by heat, and additional heads may be activated by heat and discharge, as well.

Wet pipe sprinkler systems are ideal for most industrial, commercial, retail, or residential facilities that do not store expensive electronics, documents, or art that could be destroyed by a sprinkler discharge. Wet pipe systems also must be installed in buildings that are not susceptible to freezing.

Dry Pipe Sprinkler System

So, a dry pipe system sounds obvious, right? Unlike a wet pipe system, dry pipe systems do not have water constantly stored. Instead, the system utilizes compressed air, held in a remote valve, that remains closed to prevent water from entering the pipe. Once the sprinkler heads detect heat, the compressed air in the pipe is released and the water is free to enter the pipe and discharge through the sprinkler heads.

Dry pipe systems are very useful in facilities that are susceptible to freezing, since the water in a wet pipe system would freeze in the pipe. This makes dry systems ideal for commercial freezers. Additionally, they are ideal systems for parking garages, industrial warehouses, and loading docks.

In-Rack Sprinkler System

Warehouses are usually large spaces and require more substantial sprinkler equipment to provide sufficient coverage. In addition to sprinkler systems connected to the ceiling, heads can be installed inside a warehouse storage rack. These in-rack systems are designed to quickly extinguish a fire on a specific rack and contain the fire to the single rack. You can imagine the headache of one rack catching fire and having sprinkler discharge over multiple, nearby racks.

In-rack sprinklers systems are ideal for facilities that have large industrial racks or that store highly hazardous items like flammable liquids that could spread a fire quickly.

Pre-Action Sprinkler System

Pre-action sprinkler systems work very much like a dry pipe system in that water is not stored within the pipes. Pre-action systems have a similar valve that restrains the water from entering the pipe before activation.

The pre-action system discharges in a two-step process:

First, the system identifies heat or smoke. Once the fire is confirmed, the pre-action valve is activated, allowing water to flow into the pipes and to the sprinkler heads.

The second step provides an extra level of protection against inadvertent discharges, which makes pre-action systems perfect for water-sensitive environments.

Pre-action systems are ideal for fine art storage, libraries, museums, or archival vaults. If it’s invaluable and water would destroy it, a pre-action system is your best bet to make sure that water is never inadvertently discharged.

Quell Sprinkler System

Quell systems were created by Tyco Products, a world leader in sprinkler technology. This system is known for using the “surround and drown” method. And it works a lot like it sounds. The goal is to get as much water discharged as quickly as possible to saturate the area on fire. Quell systems also do not rely on in-rack components or anti-freeze. This allows the facility to stock more classifications of inventory, attain higher roof heights, and allow for more flexible facility stocking configurations. Best of all, all Quell systems are backed by a 10-year manufacturer’s warranty.

Quell systems are common in a variety of industrial and commercial facilities, including outdoor storage facilities, frozen storage facilities, and unheated warehouses.

Early Suppression, Fast Response (ESFR) Sprinkler System

ESFR systems focus more on finding the origin of the fire rather than just controlling the spread of a fire. The sprinkler heads for an ESFR system release larger droplets of water with greater momentum than conventional sprinkler heads. This leads to twice as much water being discharged on a fire than conventional sprinkler heads in the same amount of time. The ESFR sprinkler heads also begin discharging in half the time of conventional heads.

ESFR systems are traditionally used in warehouses to protect high-piled inventory or palletized inventory. ESFR systems are a good alternative to in-rack systems if you need to move storage racks around more freely.

No matter what type of sprinkler service you install, the common goal is clear – to protect life and property and minimize the water damage after discharge. Understanding how these systems work will benefit you as you work with your Life Safety provider to install the preferred sprinkler system type.

For more information about sprinkler system types, please click here.